Services

Calculation & Offer

Alkom Management Team controls economic efficiency in the cost estimate and consider the technical possibility against the costs. Our team benefit from the fact that we within the Alkom Facade can offer a wide range of knowhow, both in technical and business management terms.

Design & Planning

Alkom Management Team procedures with the latest software systems for the planning and design department in projects involving many participants. The addition processes such as the material procurement, detailed design, work preparation and construction logistics are also supremely coordinated and make it achievable to act adaptably to changes.

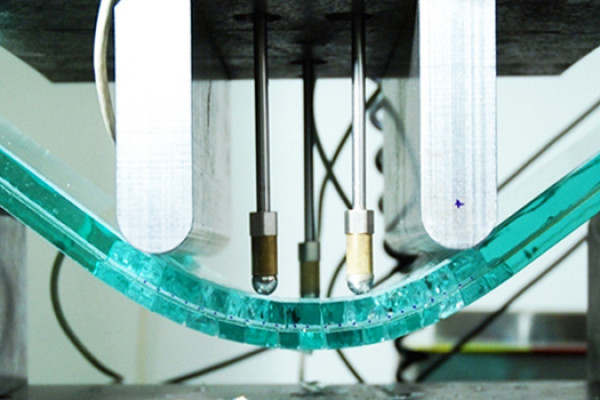

Testing & Mock-ups

Alkom Façade Systems can be calculated and tested using prototypes and mock-ups. The Systems are produced by samples in size of the original which are assembled on our construction site, on a test stand or at a test institute. The systems have performed by universally prescribed inspections, load tests and classifications and approvals before installation.

Production

Our knowledge is established on a strong understanding of the most various materials and experience in the machining and processing of aluminum, steel, composite materials, glass, and natural stone materials. Alkom Production Team produces façade elements, windows, doors, and composite panels by the latest CNC machines, in a custom-made method and based on the highest, tested quality.

Installation

The installation time on the construction site logistics holds out significant savings potential. Alkom installation team is consequently concerned at an early stage to identify potential problems during the planning phase, to find the most effective and safe installation procedure and to ensure a smooth procedure.